Our Factory

At SMT PARTS SUPPLY LTD, our factory is the cornerstone of our ability to provide high-quality SMT solutions, precision components, and reliable machine support to electronics manufacturers worldwide. With years of experience and continuous investment in technology, we have developed a comprehensive manufacturing and development ecosystem capable of addressing complex challenges, from custom-designed parts to replacements for discontinued factory components.

1. Production Line

Our production line is fully equipped with state-of-the-art SMT machinery, automated assembly systems, and precision inspection equipment. Every step of the production process is carefully monitored to ensure accuracy, consistency, and efficiency, from the initial material intake to the final product inspection.

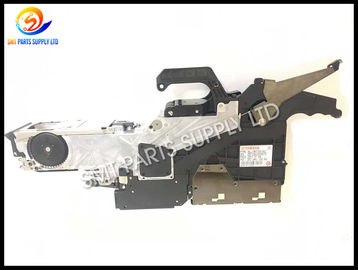

We specialize in producing a wide range of customized components, including nozzles, feeders, mechanical parts, and electronic assemblies, tailored to the unique specifications of each client. Our production capabilities also extend to high-fidelity alternative parts, designed to replicate original functionality for discontinued or obsolete components. This ensures that manufacturers can maintain uninterrupted production even when original parts are no longer available from the OEM.

Our production lines are divided into multiple dedicated areas, each focused on a specific aspect of SMT manufacturing:

-

Precision Component Fabrication: Producing high-accuracy parts such as nozzles, feeder components, and specialized assemblies with tight tolerances.

-

Assembly Lines: Automated and semi-automated lines capable of handling both high-volume production and low-volume, high-mix orders.

-

Quality Inspection & Testing: Each component undergoes functional testing, dimensional inspection, and stress tests to ensure it meets the highest standards.

We also prioritize lean manufacturing practices, optimizing workflow, reducing waste, and ensuring that every part is produced efficiently without compromising quality. This focus on precision, repeatability, and efficiency allows us to provide clients with products that are not only reliable but also cost-effective.

The production team is composed of highly skilled technicians and engineers, trained in the latest SMT technologies and industry standards. Their experience enables them to troubleshoot complex issues, maintain optimal machine performance, and implement custom production solutions. By integrating automated processes with expert manual oversight, we achieve the highest level of quality control.

With our production line, clients can expect short lead times, consistent quality, and the ability to scale production according to demand. Whether manufacturing custom parts for new equipment or producing replacements for obsolete components, our factory is capable of meeting the most demanding SMT production requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!